Universal Is [and other v-cooks?] have an optional dust cover which is, because of the design, often broken. They seem to break at the same point, the transition from dust cover to attachment tab. I believe that the dust cover should have been made without the cutout in the center, which would have prevented the failure in the first place.

Universal Is [and other v-cooks?] have an optional dust cover which is, because of the design, often broken. They seem to break at the same point, the transition from dust cover to attachment tab. I believe that the dust cover should have been made without the cutout in the center, which would have prevented the failure in the first place.

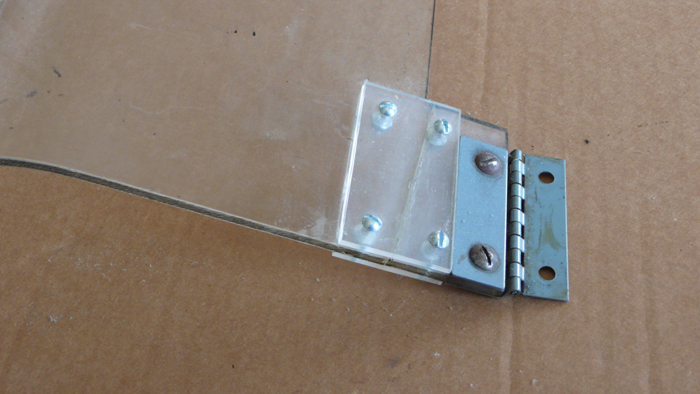

This is a very simple repair, something anyone can do, but I don’t think it would have occurred to me if I hadn’t seen it on one of the presses at the King Library Press. The Universal I there has the dust cover repaired using one plexi patch and 4 screws on each side. It works but still flexes a little at the break. I improved on this repair by using a patch above and below the break. Plexiglass can be purchased from any glass store, and can be cut by scoring & bending just like glass. Finish the sides with sandpaper. Clamp the four pieces [2 original broken pieces, top patch, bottom patch], one side at a time, and drill holes with a normal drill. Use appropriate size bolts & nuts to hold it all together. This works very well and extends the stress into the wider part of the dust cover, so it shouldn’t break again.

Hopefully, your broken dust cover hasn’t been thrown away. I got lucky, maybe you will too.

hope this helps – alex, press eight seventeen – lexington kentucky

I have the Vandercook forms for most or all of the plexiglass dust covers and have been contemplating making the more popular ones available again, like SP-15 and Univ I. It’s just one of many projects waiting in line, as well as the cloth dust covers. The dust covers are a bother at times, but serve their purpose of keeping floating crap in the air from landing on the rollers while the press is in use. Schools view these as safety items for keeping student’s hands, hair, and clothing from getting taken up in the rollers, and safety is one of their paramount concerns.

The plastic dust covers were an optional item, and had to be specified when the order was placed. The cloth dust covers were also optional, and in later years, Vandercook had a cheap attack and started making them out of plastic. I have a prototype one underway where the Vandercook world logo would be in the center in stitchery, but I went overboard and made the trial one too big with a ton of stitches–looks nice, but costs way too much to produce. Vandercook did use a stitched logo in the 40s and 50s, but it was simple and reasonably small with the word Vandercook stitched with a simple border around it–in those days, the only source was from uniform companies, and that’s who made them for Vandercook.

affordable is good, free is better. I have more time than money so I go that route.

I like the dust cover for keeping paper dust out of the ink while printing.

works for me, but thanks for your thoughts.

-alex

That’s a good point, Paul. I think a dust cover for the whole press like the canvas ones that Vandercook used to make would be much more useful. They serve to keep the whole press clean when its not in use and then get the heck out of the way when its time to print.

http://farm1.static.flickr.com/72/173337641_97d964e356.jpg

Daniel Morris

You’re right, Daniel, a dust cover would be a simple bend. I have had more complicated one-off point of sale racks made at reasonable prices.

Personally though, I wouldn’t bother. I prefer to have an unobstructed view of the inked rollers so that I can immediately see any anomoly that appears on the surface: a heavy spot of ink, a sliver of makeready or polymer or a build-up of paper fluff during a long run using a mouldmade sheet.

Any plastics machining shop should be able to remake this part using heat and a bending form if you have the original for them to take the measurements from. I have used Maritime Plastics in Eastport, Maryland for this and they produced the part I needed with good results.

Daniel Morris

Plastics dust covers were standard on Universal and SP series presses except the SP13, which has a separate inking carriage similiar to the kind sold as an option on some early models such as the 15, the 20, and the 32 (c.1914-26)

Other later models with plastics dust covers were the 15-20 and 15-21, (both released in 1955), the 425 (1958) and the 319 (1960). I am not aware of any other models that have them.