I recently repaired an SP20 at the University of West Georgia on which the carriage had become stuck during the return travel. The photos above shows that top carriage bearings on the operator’s side had been removed during a previous repair attempt.

I recently repaired an SP20 at the University of West Georgia on which the carriage had become stuck during the return travel. The photos above shows that top carriage bearings on the operator’s side had been removed during a previous repair attempt.

Typically what happens on SP series presses is that the trip spring inside the carriage side plate breaks causing the trip arm that shifts the carriage eccentric between print and trip to move freely.

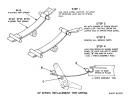

Although it is difficult to access, Sheet 302 of the manual shows a diagram and outlines the procedure for replacing the spring.

Although it is difficult to access, Sheet 302 of the manual shows a diagram and outlines the procedure for replacing the spring.

A broken trip spring by itself doesn’t jam the carriage. In this case the retaining clip that hold the carriage eccentric arms linked to the trip arm stud had popped out. This caused the trip arm to flip over backward and hang down behind the print/trip pin that projects from the side of the bed. When this happens it impossible to repair the trip arm assembly without removing the side plate.

To remove the side plate, I had to also remove the tie rods, and the oscillating roller assembly. (The bottom carriage bearings were removed only for cleaning. Upon removing the side plate, I found that the brass Cylinder Eccentric (X-19423) remained attached to the crank shaft. A UGW Facilities worker assisting me, used a bearing extractor to remove it.

To remove the side plate, I had to also remove the tie rods, and the oscillating roller assembly. (The bottom carriage bearings were removed only for cleaning. Upon removing the side plate, I found that the brass Cylinder Eccentric (X-19423) remained attached to the crank shaft. A UGW Facilities worker assisting me, used a bearing extractor to remove it.

I then reassembled the mechanisms and new trip spring onto the side plate, I also reinstalled the carriage bearings, then remounted the side plate.

In consultation with Fritz beforehand, he suggested that the actual breaking of the trip spring was caused by another previous repair: the connecting bar between the trip/print operating handle and the trip/print pin that moves in and out of the side of the bed has a slot for a screw to hold it close against the bed press. The original low profile screw had been replaced with a hex head bolt, shown below, that having worked loose, made contact with the rear bottom carriage bearing. The operator forced the carriage past the bolt and this may have caused the trip spring to break.

In consultation with Fritz beforehand, he suggested that the actual breaking of the trip spring was caused by another previous repair: the connecting bar between the trip/print operating handle and the trip/print pin that moves in and out of the side of the bed has a slot for a screw to hold it close against the bed press. The original low profile screw had been replaced with a hex head bolt, shown below, that having worked loose, made contact with the rear bottom carriage bearing. The operator forced the carriage past the bolt and this may have caused the trip spring to break.

After sharing my experience with Fritz, he sent me this Vandercook engineering change document for the SP series roller latch spring intended to eliminate disassembly of the carriage:

Fritz writes: “I interpret the change order as recognizing a design glitch where the loop of the end of the trip spring was almost a full circle and when the trip spring broke, they couldn’t get it off, thus a design change. We had new ones made for the -15 and -20 from the original blueprints and the spring company said “not a problem” though it sure looked like a problem to me.”

Fritz writes: “I interpret the change order as recognizing a design glitch where the loop of the end of the trip spring was almost a full circle and when the trip spring broke, they couldn’t get it off, thus a design change. We had new ones made for the -15 and -20 from the original blueprints and the spring company said “not a problem” though it sure looked like a problem to me.”

NA Graphics has these springs, but which one depends on the serial number:

Coil spring BRS-3 for serial numbers 20900–23378

Flat Spring X-22980 for serial numbers 23379–30014

Contact Fritz at nagraph@ekiva.net

Please tell me your serial number for the census.

I have an SP-20 with a broken trip spring. Where I purchase a replacement?

I didn’t see any such tag.

Hey Paul,

Who’s name was on the “For Service” tag on this press?

Daniel Morris

The Arm Letterpress

Brooklyn, NY

Thanks for this illuminating post Paul – I found it very useful as I am in the process of restoring my sp-15 which has a broken trip spring. I’ll take a closer look and make sure everything is in order when I get to replace it. The post also explains why, in the bag of spares that came with my machine, there are two broken trip springs with closed loops – I couldn’t work out why they were different to the replacements i have, but now it’s obvious – the open loop avoids the process of taking the side panel off.

Thanks!

John Christopher

Arcane Devices

Gerald: you’re right, there is much more to the story. Thanks for letting me know I forgot to describe this task. I was striving to be to acccurate, but didn’t want to be too tedious. I will fill in the gaps for the benefit of everyone.

When I pulled the side plate the Eccentric and Trip Arm were disconnected. The Trip Arm is bolted to the side plate while the Eccentic simply sits in the hole of the plate. If one thinks of the Eccentric like a collar, the fit is tigher on the inside against the crank than it is on the outside against the side plate.

After removing the Eccentric, I cleaned and lubricated it and the crank. After reassembly, I tested the trip and immediately the trip arm flew away from the eccentric. I removed the side plate again and as before the eccentric remained on the crank. Now cleaned and lubricated, there was less resistence, but I no longer had the extractor so I gently used a pry bar to ease it off the crank. I reassembled the mechanisms and this is where I fully understood the importance of the retainer clip.

As a matter of due diligence, I did readjust all the carriage bearings. With the carriage in the middle of the bed, I slipped a .003″ brass shim between the bearing and the rail, then snugged the eccentric bolts, then rolled the carriage off the shims. I tested impression as suggested in your article “Adjusting Cylinder Carriage Bearings…”:https://vandercookpress.info/articles.html#adj, by locking up type high bearers in the bed, pulling a blind proof and examining the sheet looking for even impression side to side. (Unfortunately, it was missing the ratchet pawl so I wasn’t able to pack the cylinder. I had to lay the test sheet and tympan directly on the bed and roll the carriage over it.)

Paul

Quite interesting. Congratulations. I have had, on too many occasions, the need to pull that operator’s cheek of a SP-20. The linkage design is quite bad. The last incident was where one of the links was simply so worn out we had to invent a holder for it.

I have two questions though. I don’t recall having to pull Cylinder Excentric with a bearing extractor (unless it just came out on its own). Also, I have always had to readjust the carriage bearings when the cheek was pulled, as it is near impossible to get them back in as is. [Major pain in the ass. I hate SP-20s (I’ve had four of them over the years).]

How did you do this without having to readjust? Maybe I’m missing something?

Gerald

http://BielerPress.blogspot.com